Energy

Reaching a carbon neutral world will only be possible through breakthrough innovations

Among all human activities which contribute to global warming, some are harder-to-abate, such as aviation, maritime transport or some industries (steel and cement marking notably).

Our solutions re-use CO₂ and combine it with low-carbon hydrogen to produce a synthetic molecule like e-methane, e-methanol or e-crude.

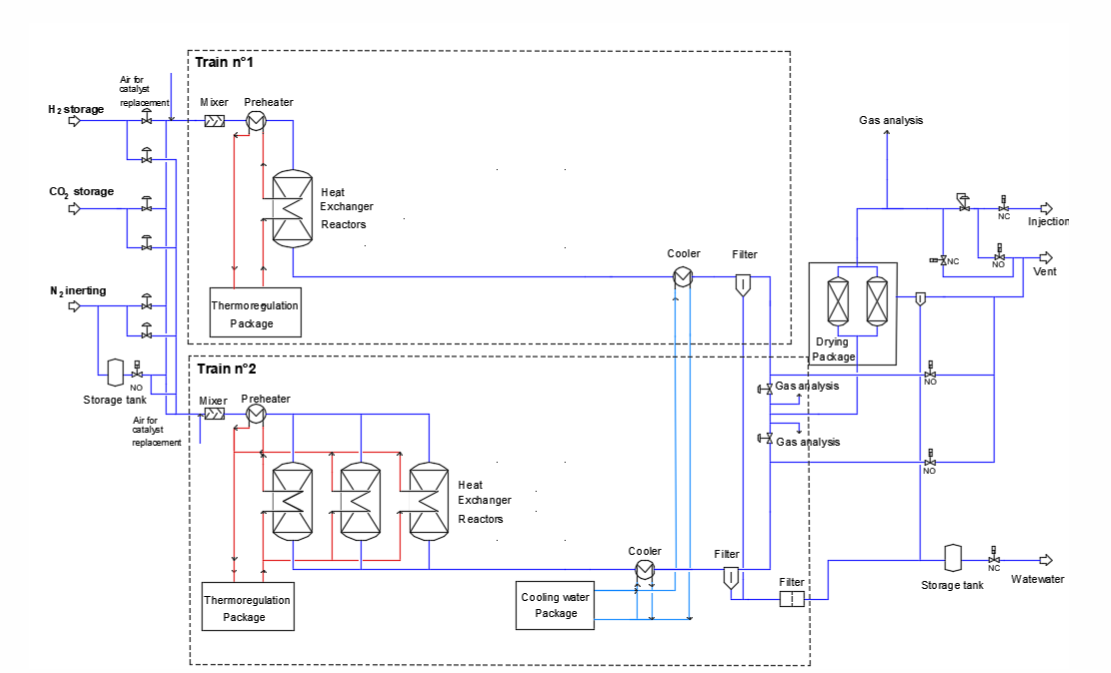

KHIMOD’s solutions for energy

End Use

E-crude

E-crude can be turned into e-fuels or Sustainable Aviation Fuels (SAFs) which is the only massive solution to decarbonize the aviation sector

E-methane

E-methane decarbonizes industries and the energy system

Water Gas Shift reaction

CO + H2O → CO2 + H2

Sabatier reaction

CO2 + 4H2 → CH4 + 2H2O

E-methanol

E-methanol decarbonizes some industrial processes and is the main solution for green maritime transportation

Methanol synthesis

CO2 + 3H2 → CH3OH + H2O

CO + 2H2 → CH3OH

Other Use

Our HER’s disruptive performance enables us to address other molecules such as:

- Hydrogen (Water Gas Shift, Reforming)

- Ammonia (Haber-Bosch)

- Higher alcohol chains

- Customized requests

How does it work?

Offer

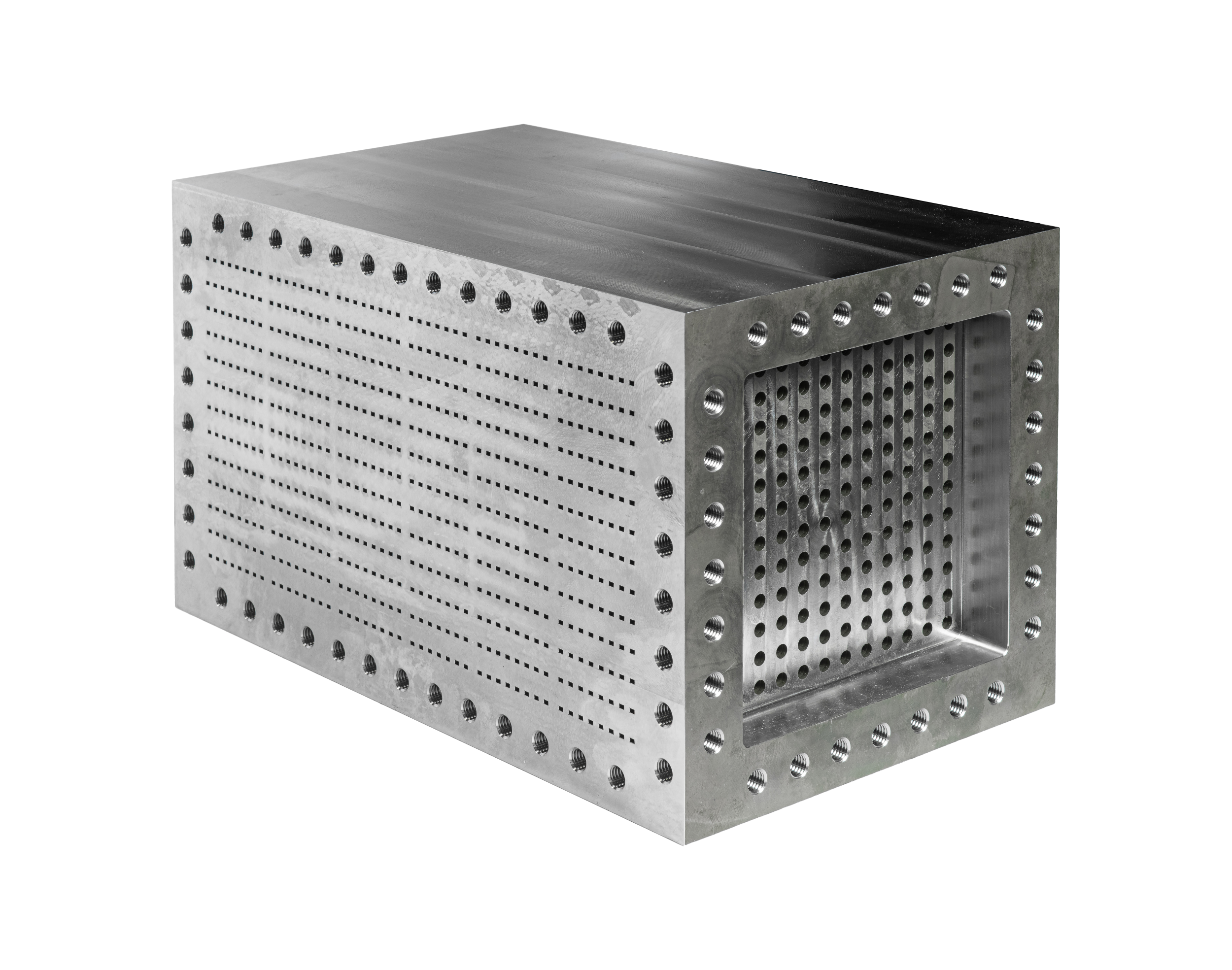

HER

A range of Heat Exchanger-Reactors (HERs) based on diffusion bonding, compatible with extreme temperature and pressure

Turnkey Units

Autonomous and modular systems from small to medium scale. Process books for large scales in the energy field

Services

Technical studies from conceptual to FEED. Long-term maintenance of HERs and units

Performance

High H2 and CO2 conversion rate

+87% energy efficiency with thermal recovery

Publications