K1

Most of the chemicals made for the fine or specialty chemical industry are made in batch.

Flow chemistry is the solution to optimize production for fine and specialty chemical industry.

Flow chemistry enables to manage safely very exothermic reactions thanks to an outstanding thermal exchange

Flow chemistry can be a solution when impurities or low yield are coming from a weak control of the temperature or reaction time

Challenging but KHIMOD can be the solution, with our patented technology coupling our reactor and ultrasounds

Handling gases, specially at high pressure, is challenging in batch but can be performed safely in flow

Flow chemistry enables to handle very hazardous intermediates safely by reducing the reactive volume

By using flow chemistry and process intensification approach, reaction time can be dramatically reduced

Faster

Safer

Greener

Better

More Cost

Effective

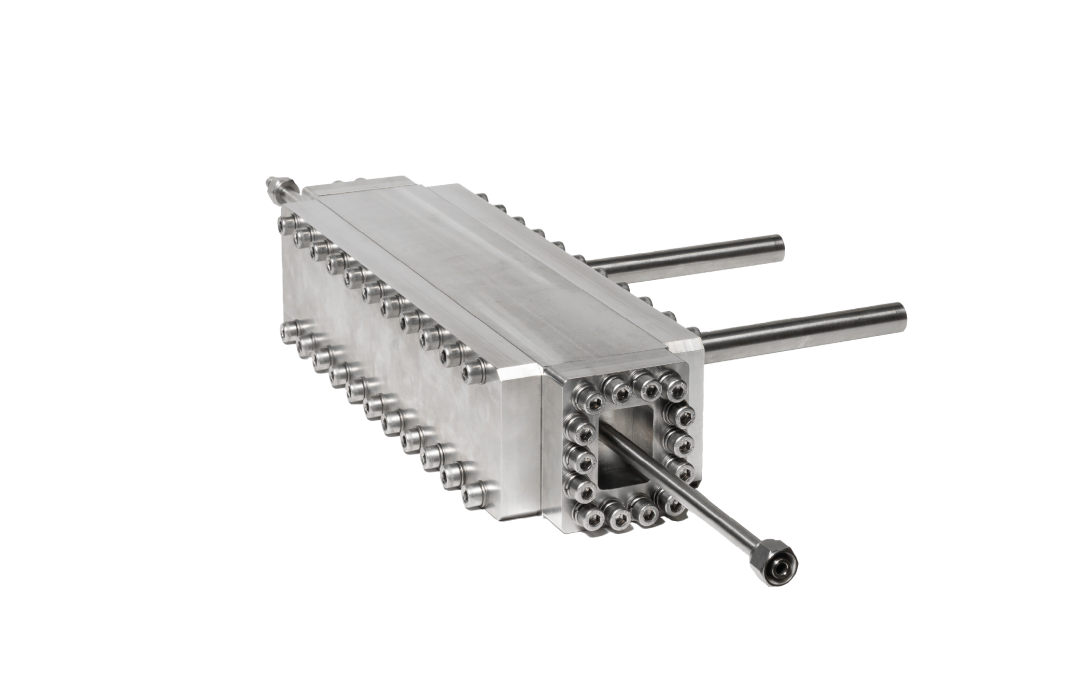

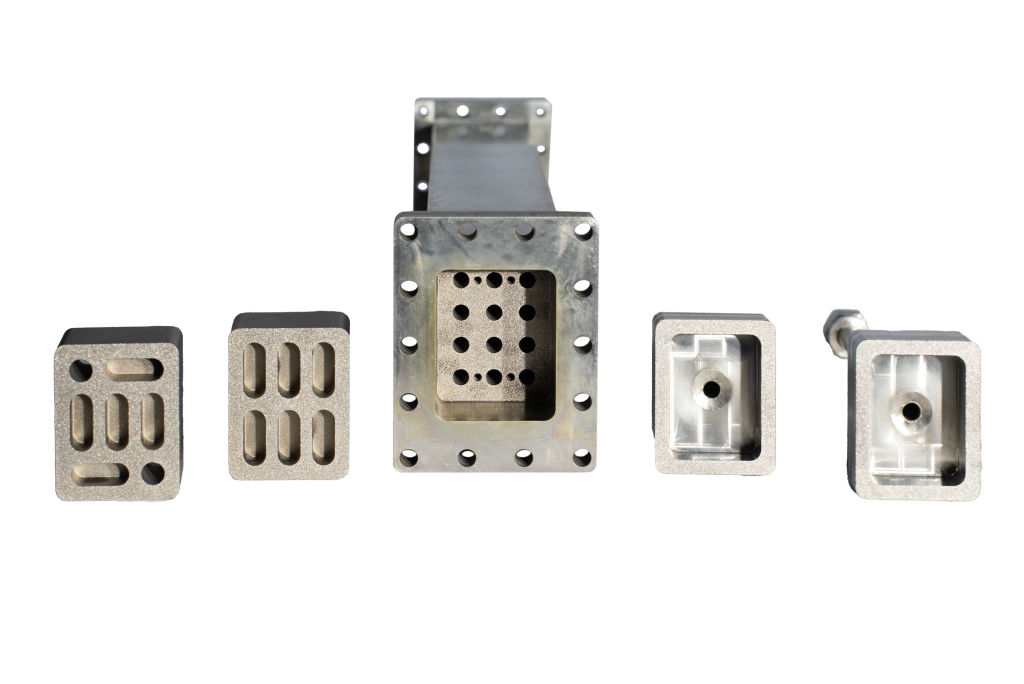

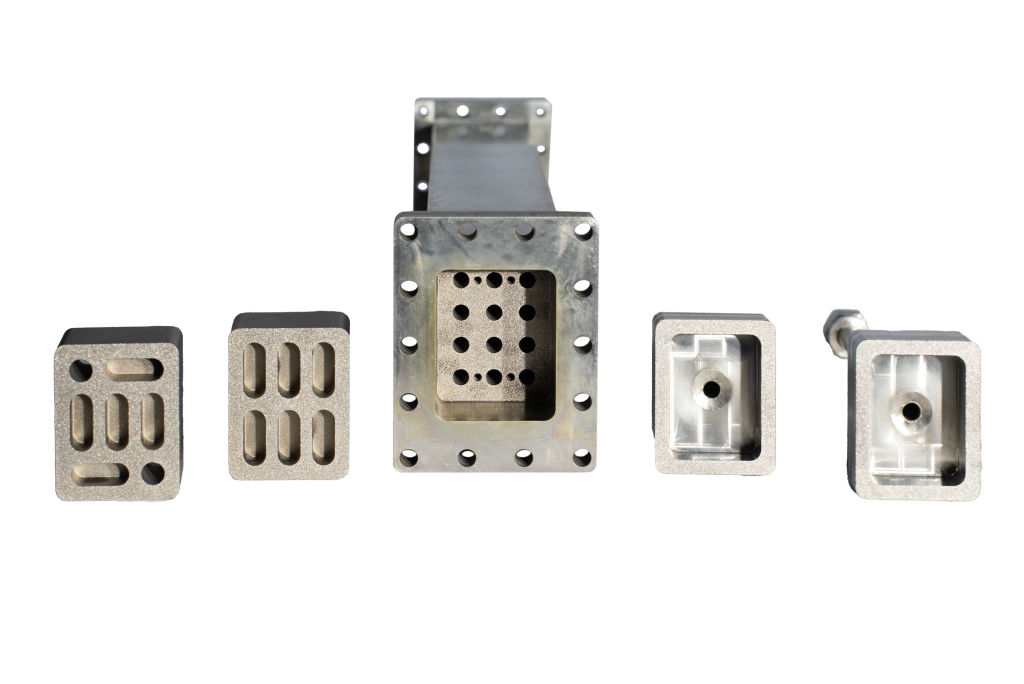

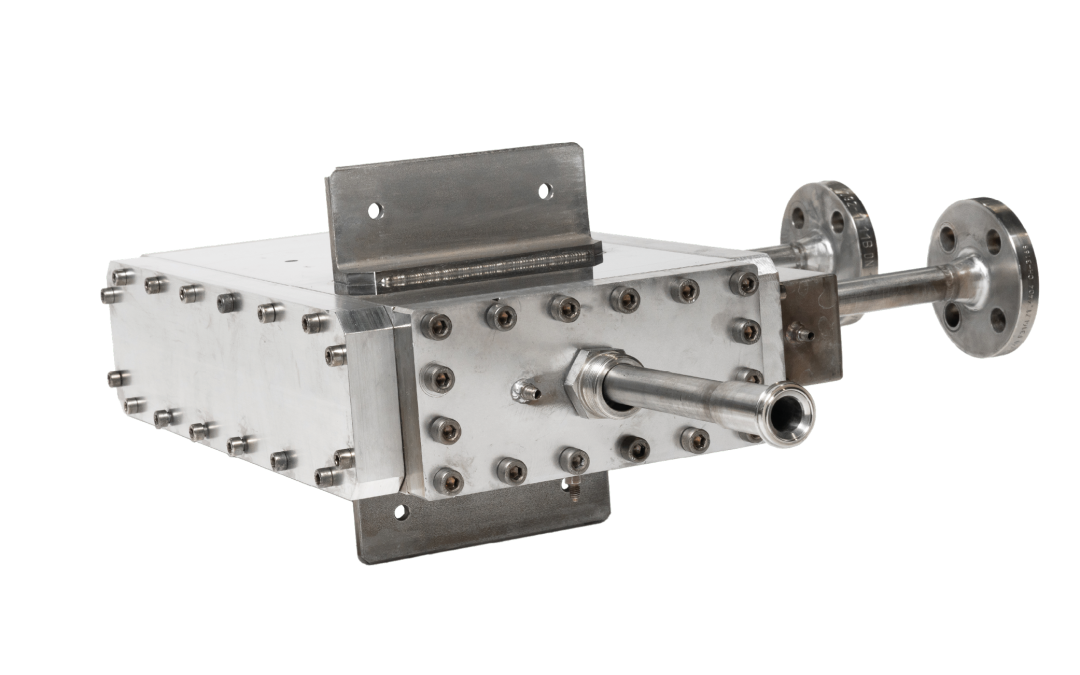

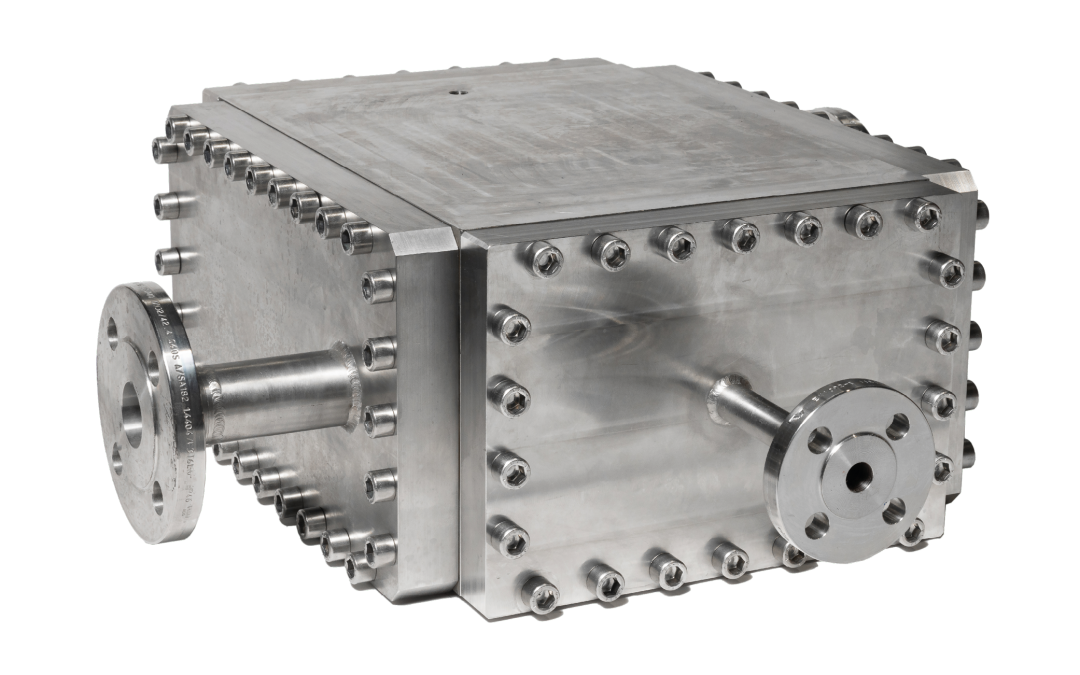

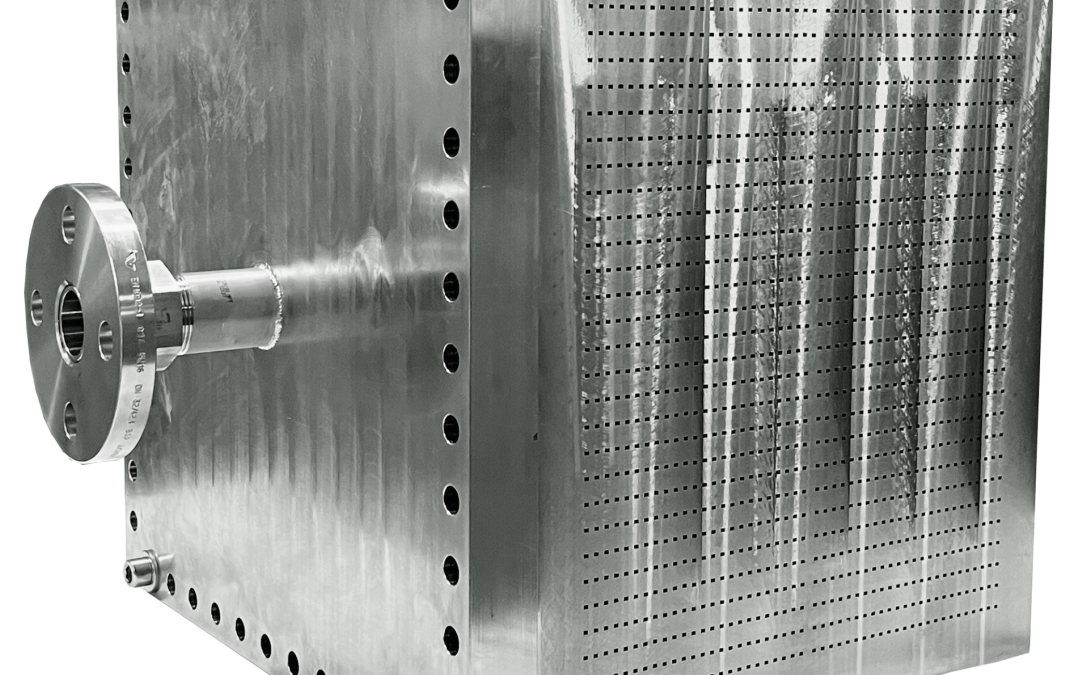

Configuration can be easily modified by changing the end caps

Opportunity to heat or cool the reagents before the reaction

Easy cleaning making it suitable for a multi-purpose workshop

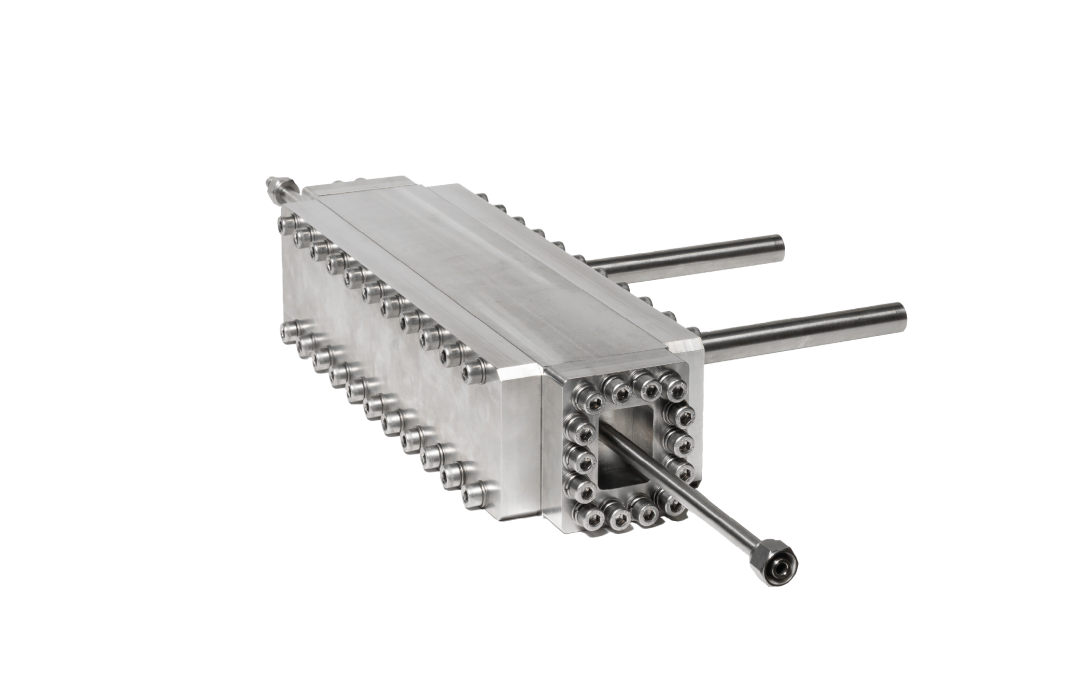

Reactive channel length adjusted to the required residence time

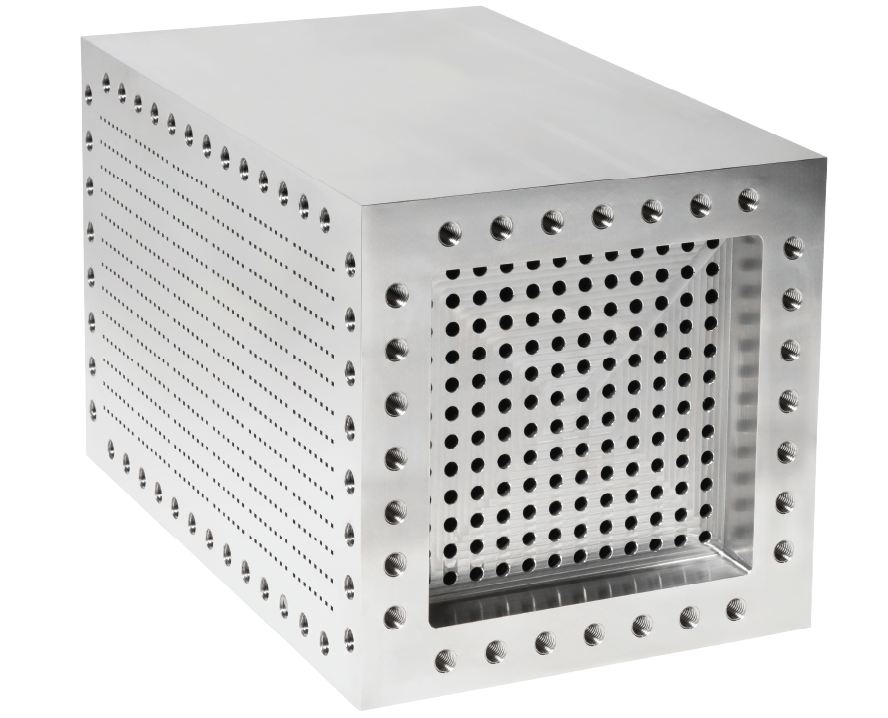

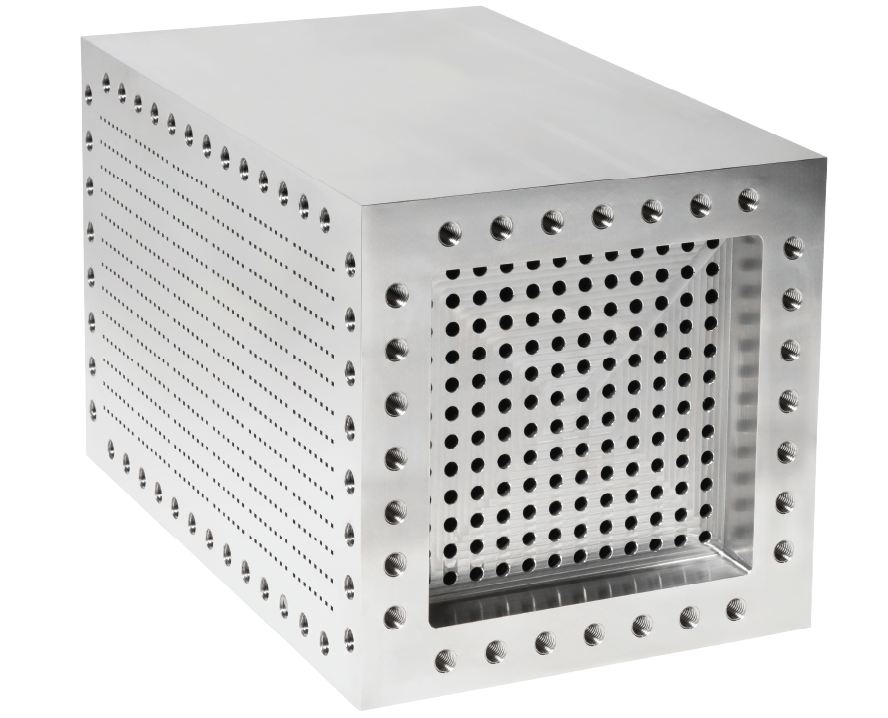

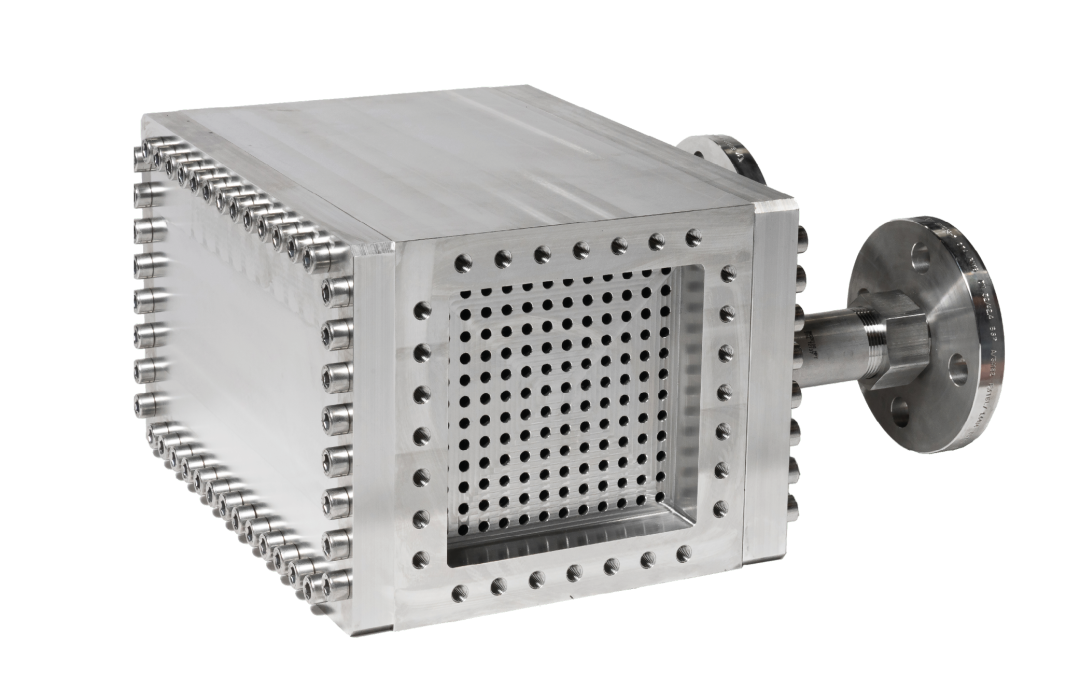

A range of reactors addressing the need of the chemical industry for process intensification.

Identical design, from lab to full industrial scale, enabling a seamless scale-up.

Channel diameter and length: 6 mm and 30 cm.

From 12 to 784 reactive channels.

KHIMOD’s heat exchanger-reactors deliver outstanding performances on flow hydrogenation with fixed bed catalysts as illustrated in the following examples: